Weighing systems are an integral part of many industries, from retail and food services to transportation and scientific research. Understanding the essential points of these systems can help to optimize and improve their accuracy and efficiency. Remember that knowing the requirements of weighing systems helps to have a reliable weighing process.

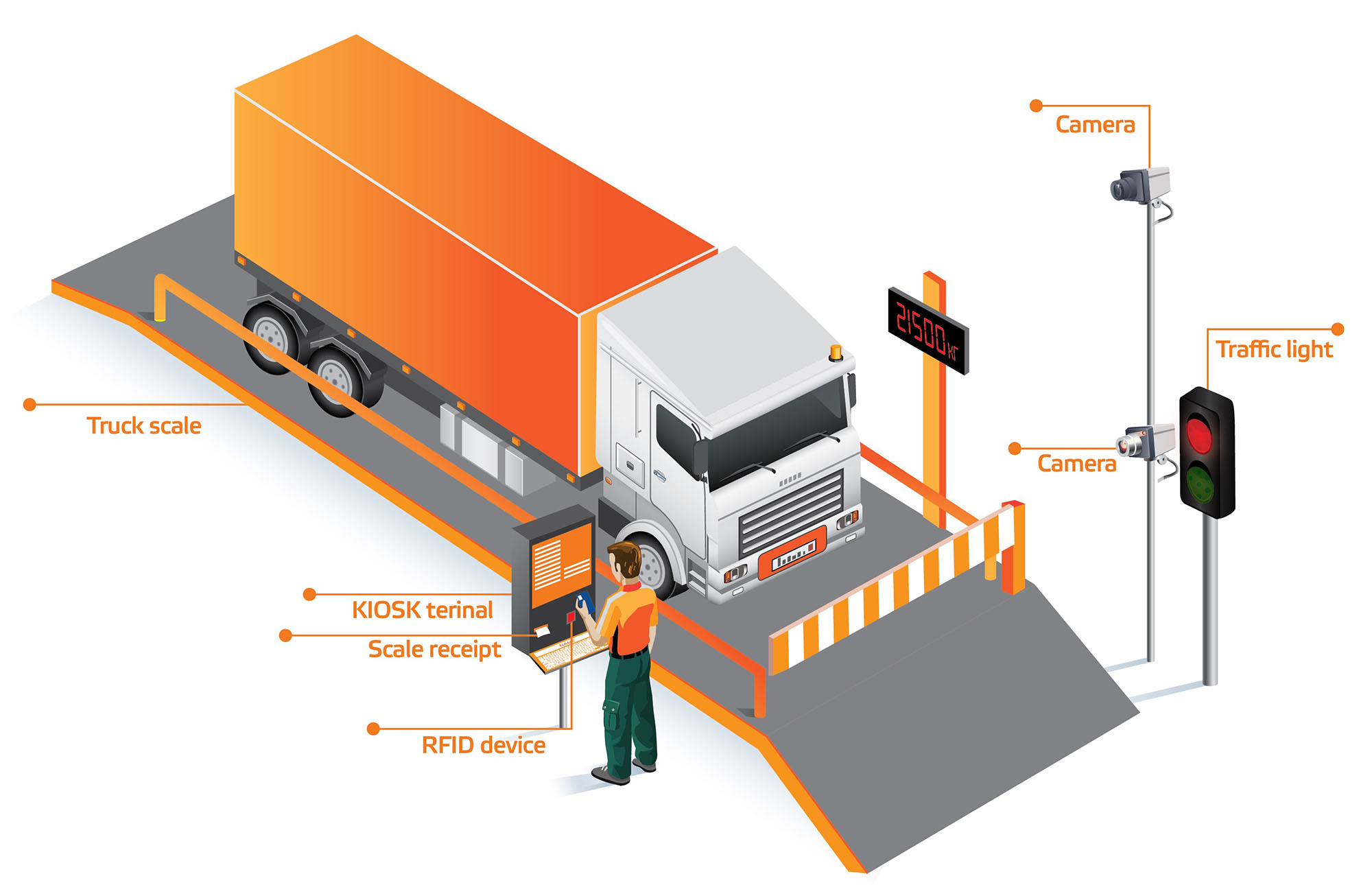

To consider weighing in transportation, it is very important to pay attention to these requirements due to the use of truck scales in industrial and open environments where the probability of error is high. In this article, the main parameters affecting weighing systems are introduced.

Types of weighing systems

Weighing systems are very different in terms of design and performance and meet different needs. Balance scales use to determine mass and are often used in laboratories due to their high accuracy. Spring scales measure weight based on the displacement of a spring under a load, commonly used in grocery stores. Digital scales, which convert mechanical input into an electrical signal, are common in various sectors due to their convenience and accuracy. Today, the most common example of weighing systems in all parts is the digital example; Other weighing systems are being removed from the weighing cycle.

Accuracy and Validity

Accuracy is the first and most important priority in weighing systems. Precision refers to how close a measurement is to the true value, while accuracy refers to the repeatability of measurements. Calibration, which involves comparing a device’s measurements to a standard, is critical for ensuring accuracy. Regular maintenance and calibration checks can prevent measurements from changing over time and ensure accuracy.

Environmental Factors

Environmental factors can significantly affect the performance of weighing systems. Temperature changes can cause materials to expand or contract, which affects measurements. Vibrations can also interfere with measurement stability. Therefore, weighing systems must be operated in a stable, temperature-controlled environment.

Data Management

Modern weighing systems often come with advanced data management features. They can store and analyze data, track trends, and even integrate with other systems for comprehensive monitoring. This capability is particularly useful in industries such as manufacturing plants and logistics, where tracking and analyzing weight data can increase efficiency and productivity.

Compliance with Rules and Regulations

Weighing systems used in commercial transactions are often subject to legal and regulatory standards. These standards ensure that consumers receive what they pay for and that businesses are charged correctly. Compliance with these standards is not only a legal requirement but also a sign of quality and reliability.

Conclusion

Understanding the basic principles of weighing systems is the key to using them effectively. By considering system type, accuracy, environmental factors, data management capabilities, and standards compliance, users can ensure they get the most out of their weighing systems.