To buy a truck scale, you should consider all costs at the time of installation and after services. Basically, before buying a product such as clothes, mobile phones, household appliances, etc. we only pay attention to the cost of its purchase. But for some instruments, considering their initial cost is not enough, you would also think about the cost of service and maintenance.

While the price of the truck scale is an important parameter to choose, maintaining its accuracy and reliability during the period of use is also essential. Choosing a reliable scale can reduce maintenance and repair costs for several years and protect you from hidden losses, but the service and maintenance costs of a scale can never be eliminated. In the following paragraphs, this topic is described with a focus on details.

The Cost of Buying a Truck Scale

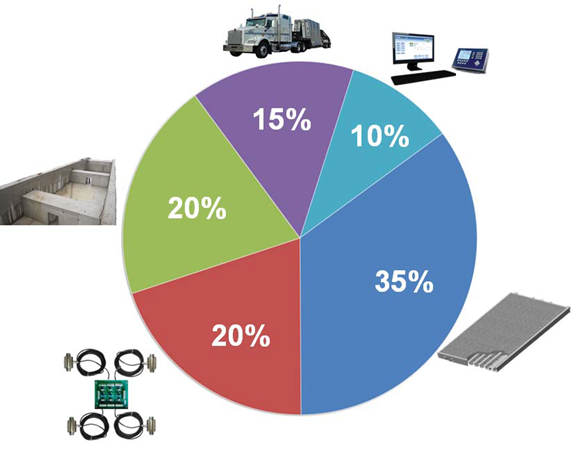

In this part, the price of each component is elaborated based on percentage. We have demonstrated that how much each part costs you.

The table below shows the percentage of the average cost that is allocated to each compartment in the purchase of a scale.

| 35% | Platform |

| 20% | Load Cell System (including several load cells, junction box and connection cable) |

| 20% | Site preparation |

| 15% | Transportation and logistics |

| 10% | Indicator and software |

As mentioned above, a buyer should calculate the costs of a truck scale in terms of purchase and maintenance costs. The question that comes to your mind after calculating these components, despite these costs, it is still profitable to buy a truck scale or not?

It is better to use the following items to calculate the income of a truck scale to find the right attitude towards income and expenses.

1. Calculate the value of the times of using the

during a day and also calculate it for a year.

3. Calculate the maintenance and personnel costs of a weighing system so that you can deduct them from the resulting income.

4. Think about what additional weighing services you can offer truckers and consider them all into your decision.

Maintenance costs

You pay once for the purchase of a scale, and after installation, there is no longer any cost. But note that this is not the end of the story as this instrument is one of those that constantly needs after-sales service to ensure accurate performance.

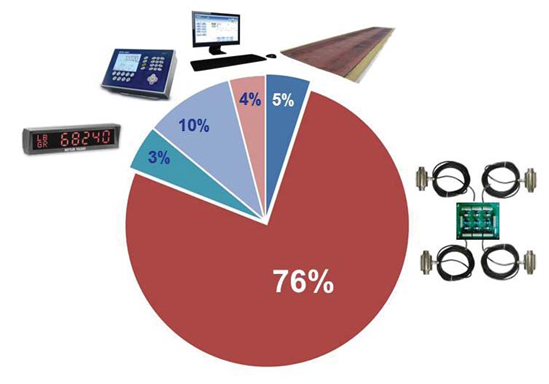

You periodically need to receive after-sales service depending on the functioning of the scale and the daily maximum weight you weigh. In the table below, the components that you have to periodically check are presented, the percentage of costs is also mentioned.

| 76% | Load Cell System (including several load cells, junction box and connection cable) |

| 10% | Indicator |

| 5% | Platform |

| 4% | Software |

| 3% | Accessories (license plate reader, traffic lights, etc.) |

As you can see in the picture, a significant percentage of the costs after buying a truck scale is related to the load cell. The load cell is the most sensitive part of a truck scale, which directly affects the accuracy of the scale. Other components also have costs, but their percentage is very less in comparison with the load cell.