The truck scale platform must physically fit the largest truck you intend to weigh. Vehicle sizes can be different in different parts of the world, but this system has been integrated over the years, so, the percentage of wrong orders of truck scale according to the size of the vehicle has been reduced around the world.

It is better to choose a truck scale in a way that can cover a wide range of trucks and trolleys so that you don’t need a separate scale for each vehicle. With this smart choice, almost 10 to 20 years, you can use this product for several vehicles.

Many manufacturers of this product offer their dimensions based on international standards, but the dimensions of a truck scale can also be customized. Even in some cases, you may use a new scale platform, different in size, for an already installed foundation, but our recommendation is that you should re-order a new one as a scale that all components are installed and operated in harmony, leading better accuracy and performance.

The Length of a Truck Scale

In applications where the entire truck must be weighed, the scale must be long enough to accommodate all the wheels of the longest truck you desire to weigh. For example, for a truck, you should use a truck scale whose platform length is 8 meters and it is designed to weigh vehicles up to 8 meters long. By purchasing an 8-meter-long truck, you can also weigh all smaller vehicles.

The width of a Truck Scale

The width of a normal truck scale is 3 to 3.5 meters on average. Greater width can increase the maneuverability of the truck on the scale. Ordering a wider width depends on the installation site of this product, if the space is such that the truck does not have a suitable space to maneuver before entering and exiting the scale, it is better to consider a larger width.

Installing a Truck Scale Based on the Vehicle Axis

For weighing road vehicles, there are three main types of this product configurations that can be used based on your expectation applications of the truck scale: single-axle, two-axle, and multi-axle.

Single Axle Truck Scale

A single axle type of this product usually consists of a weighing module or platform. The width and length of the single axle truck scale is designed in such a way that the axles of the vehicles are weighed easily when it is on it. One of the reasons for choosing a single-axle is cost-benefit. Because it is smaller than the two-axle ones and it significantly reduces the cost of the installation, and the scale itself has a lower cost compared to the two-axle and multi-axle scales. By weighing each axle separately, these scales can provide an estimate of the total weight of a truck. However, this method is not accurate enough to be reliable for very large trades. These scales are very suitable for environments with road restrictions.

Two-axle Truck Scale: truck vehicles

The structure of this product is usually made of several load cells that are formed two-axles truck scale. As the scale has all the features of weighing the entire truck at once, it is more accurate and reliable for large industries.

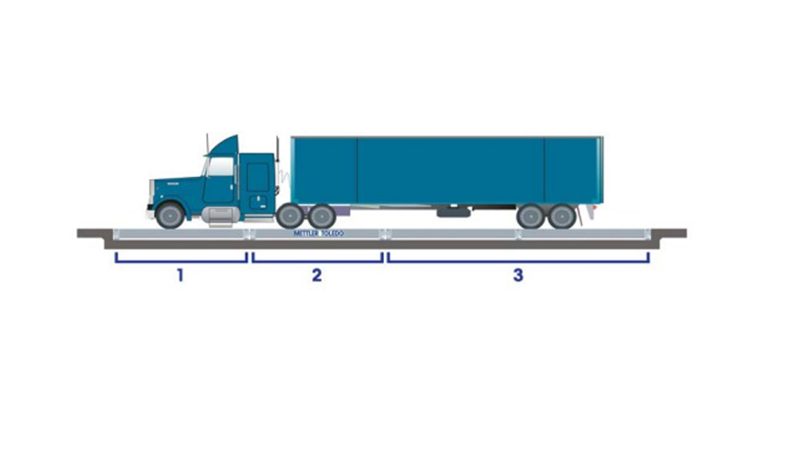

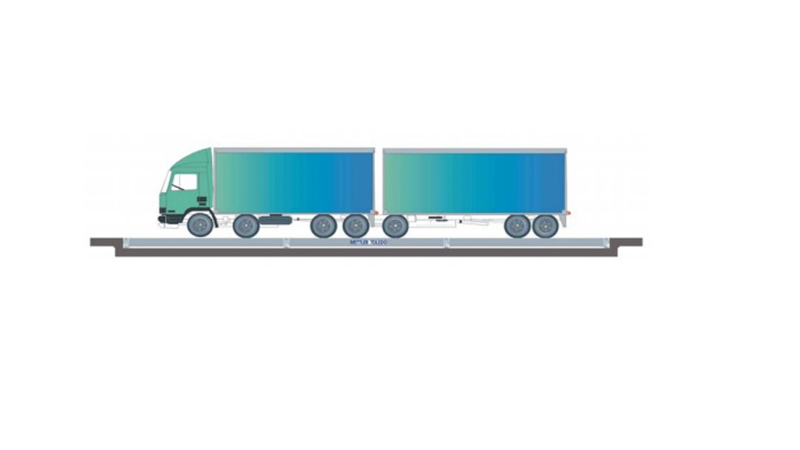

Multi-axle Truck Scale: trailer vehicles

The multi-axle truck Scale is very similar to the two-axle weighbridge, but with a key difference in the number of junction boxes that receive the weighing signals is more. The number of platforms used in this product is more than the two-axle scales with a length of bigger than 8 meters which are installed along each other.

In this product, it is possible for each junction box to be read separately by the indicator, in this case, it is possible to weigh the axles separately and weigh the entire trailer at once.

These scales are more expensive than single-axis and two-axis scales and are often used in big industries.