Hydraulic load cell is one of the most common load cells used in truck scales. Compared to other load cells, it has a number of advantages and disadvantages that make it the best option for some situations.

| Pros | Cons |

| Moisture resistance | The price is higher than the analog model |

| Can be used in hazardous environments | It has fluid lines and the possibility of leakage and reduced accuracy |

| Lightning resistance | They are mechanical, they do not have features such as a monitoring and diagnostic system |

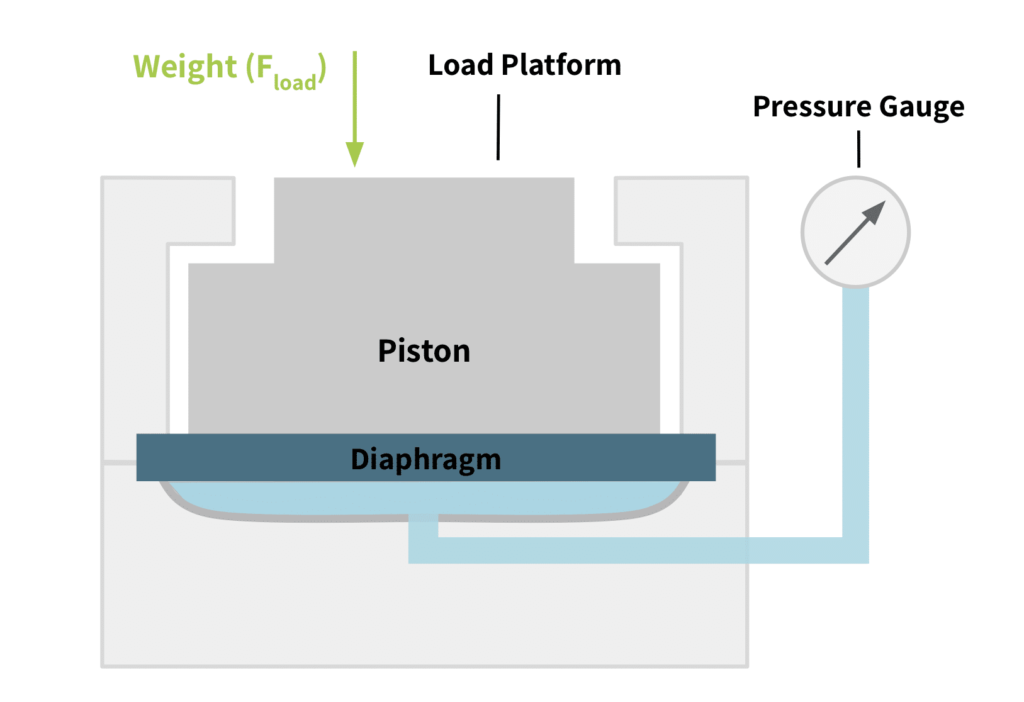

These load cells are non-electric and consist of piston, base, cylinder and diaphragm. In these load cells, liquids are sandwiched between the base and the diaphragm. By applying weight on the tuck scale deck, the piston puts pressure on the diaphragm and the hydraulic pressure change moves the fluids in the piston.

Hydraulic load cell performance

Each load cell is connected with a fluid line individually to a totalizer unit located in the weighing chamber. In some cases, this communication route reaches more than 150 meters in a truck scale.

In the totalizer, the fluid pressure received from each load cell is combined into a single force and vertically exerts pressure on an analog load cell. The analog load cell is connected to the scale display and calibrated to convert fluid pressure to weight.

Notes on hydraulic load cells

Pay attention that the use of hydraulic load cells in high-risk areas such as places where there is an electric spark may lead to fire and explosion. For these environments, it is better to use low-powered strain-gauge load cells.

In facilities such as solid waste processors that require high-strength load cells, hydraulic systems are mainly used. For the maintenance and repair of hydraulic load cells, experts in the field of liquid leakage and pipelines should be used.

One of the other advantages of these load cells is the reduction of radio frequencies or the interference of electromagnetic waves and ultimately the increase of measurement accuracy, because the pressure applied from the scale deck to the load cell is transferred to the totalizer by fluid transmission, where it is converted into an analog signal. This signal is not subject to environmental interference and has high accuracy.

Being resistant to lightning is another advantage of using a hydraulic load cell. It is better to use these load cells for truck scales that are installed in open environments. However, due to the non-technological nature of these load cells, the possibility of their use being zero is high.