Load cell is an electronic sensor for measuring weight and force. By applying force on this product, an electrical signal appears on its output wires. Load cells calculate the weight changes based on the physical changes while it is under force.

These industrial pieces are used in a wide range of industries due to their variety of applications. In the following paragraphs, all points about this product are elaborated.

Types of load cells

As load cells have wide applications in all industries, their physical design is done with different purposes. The physical engineering design of this industrial piece, the class of it and its capacity are all factors which are concerned to design its shape.

Types of this industrial piece includes single point, bending, compression (or cylindrical) and tensile load cells.

Maintenance Conditions of Load Cell

It should be mentioned that some products require different and more sensitive maintenance conditions compared to some normal products due to their sensitivity and functionality. This product is one of the sensitive products that requires special maintenance conditions. To maintain this product properly, consider the following conditions.

• Avoid forcing this product more than its capacity

• Have periodic inspections for evaluating load cells’ functionality

• Check the physical health of this product and its connection parts

• Prepare this product physical care protocol and train operators

• Protect this product from rodents and other environmental damage

• When it is necessary to remove the load cell from weighing circuit, be sure to disconnect the connection cable before transporting it

• Do not use this product over or under standard temperature mentioned in its catalogue

• Avoid the accumulation of water and various wastes around the this product and always keep the environment clean and tidy

Application of Load Cell

This product are used to measure weight in various factories. This product plays a key role in truck scale and is used to measure all goods. In different industries, from weighing fruit trucks to transportation of chemicals need to be weigh by load cells.

All trucks and shipments need to be weighed to leave one site and enter another one. This product is responsible for the correction of all weighing items. Therefore, this product has a wide and decisive function in all industries.

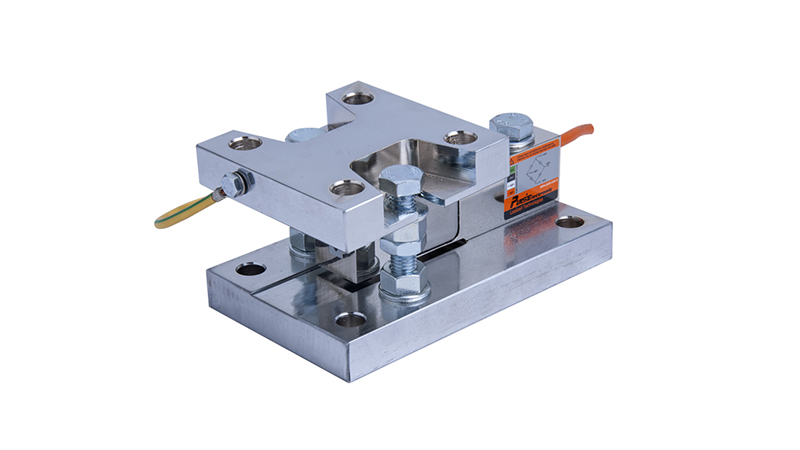

The Structure and Operation of a Load Cell

This product consists of a metal core (made of a special alloy) and a number of strain gauges, which are a set of electrical resistances and are installed in its inner core with a special adhesive.

This product changes its shape and size while it is under a force, but after removing, it returns to its original state. The degree of reversibility and deformation of this sensitive part determines the quality and accuracy of this product. The determining factors in this product is the range of resizing by which the weight is read and transferred to indicator.

Considering the Main Items of Purchasing a Load Cell

To buy any product or service, you must keep some specifications in your mind. This also applies to load cells, so before buying this product, you must determine the specifications you need.

The important items that you should consider when buying this product are explained below:

• Choosing the right load cell based on function and environmental conditions

• Choosing the right capacity

• Considering the environmental and climatic conditions on the accuracy of the scale (such as wind, friction, expansion and contraction, wire pulling, acidic and alkaline conditions, etc.)

• Appropriate design to prevent this product from outdoor threads

• Ensuring the levelness and flatness of the surface on which this product is installed